The drama student shown above appeared on the cover of the February 1948 issue of Radio News. The young thespian was an early adopter of magnetic recording technology, one of the many civilian technological advances that came from wartime industry. She used a wire recorder from Webster-Chicago Corp. to practice her diction and delivery.

The drama student shown above appeared on the cover of the February 1948 issue of Radio News. The young thespian was an early adopter of magnetic recording technology, one of the many civilian technological advances that came from wartime industry. She used a wire recorder from Webster-Chicago Corp. to practice her diction and delivery.

Of course, home sound recording had been possible for some time, thanks to disc records such as the Recordio. But magnetic recording media had the great advantage of being reusable.

The magazine contained a number of features, and it does contain a very complete look at the state of the art in 1948. The two competing formats were wire and tape. Wire held a slight lead in fidelity, but tape was easier to work with, especially when it came to editing and splicing. Interestingly, the magnetic recording tape of the time was actually paper tape with a thin magnetic coating. Typical speed was 8 inches per second.

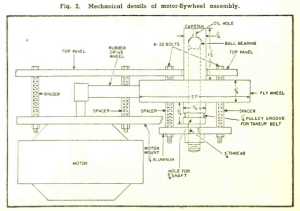

Among the features of the issue was a construction article for the tape recorder shown here. The project was said to be “well within the capabilities of anyone who has a working knowledge of electronic circuits and who has ordinary mechanical ability.” The mechanical ability was important, because all of the parts had to be made. A metalworking lathe was required, although the article noted that those without one could have the parts custom made at a local shop at low cost. As one of the mechanical diagrams shown at right shows, the construction did require some mechanical skill. Apparently, 75 years ago, that level of skill was ordinary.

Among the features of the issue was a construction article for the tape recorder shown here. The project was said to be “well within the capabilities of anyone who has a working knowledge of electronic circuits and who has ordinary mechanical ability.” The mechanical ability was important, because all of the parts had to be made. A metalworking lathe was required, although the article noted that those without one could have the parts custom made at a local shop at low cost. As one of the mechanical diagrams shown at right shows, the construction did require some mechanical skill. Apparently, 75 years ago, that level of skill was ordinary.

The recording/playback and erase heads also had to be homemade, and consisted of a coil wound on a laminated core and placed in a shielded enclosure with just a small opening for the tape. The choice of material for the core was critical, and had to be permalloy. The type of material normally used for transformer cores would not work. The best solution was to buy a particular type of audio transformer, disassemble it, and use the lamination material for winding the heads.